We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Technical Sewing Machine DIY Repairs

How to fit the top shaft bevel gear

This information relates to most Singer 300 and 400 series sewing machines, and explains how to remove, refit and retime the machine after fitting the new top shaft bevel gear.

Lay the machine on its back and remove the bottom cover, slacken the belt...

Sewing machine runs on its own as soon as it is pluged in

There is a very high chance that the foot speed controller has burnt out and has shorted across across its connections - There is only one option when this happens, replace it with a new foot control.

It is important you replace the foot control with...

Machine wont pick thread up from bobbin every now and again

Replace needle. Check threading. Check for burr on hook or on the bobbin case - Replace if there is any sign of damage or pitting. If the above do not resolve the issue, the sewing machine timing may be out of alignment and will need to be reset.

Machine wont pick thread up from bobbin at all

Look for a damaged gear under the machine, remove the bottom cover and look for a plastic gear that may have split or cracked. You may see a brocken gear tooth in the base on the machine. Look at the gears on the shafts while rotating ...

Machine is not feeding or moving the fabric

Check first that the feed dog is lifted, and under the needle plate is clean... check there is no lint between the feed dog teeth - Rotate the machine by hand using the hand wheel - Is the feed moving ? YES - adjust the foot pressure. See FAQ Sewing...

Hook is not rotating

Similar to the FAQ "Machine wont pick thread up from bobbin at all" however, if the hook is not rotating, we know the problem will be a split or cracked gear maybe under the bobbin area or bottom half of the machine, or the drive from the machines...

How to reset the feed timing

Replace parts as required first and reassemble. Always reset hook to needle timing first.Select straight stitch and turn the stitch length to a long stitch setting.Replace old needle with a brand new of size 90. Use a standard sewing machine needle.Turn...

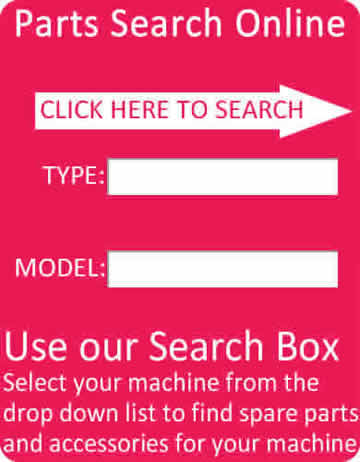

Where can I buy sewing machine parts

We have just uploaded 10% of the most popular parts, feet, gears and accessories etc, to our on-line database. We carry a huge range of sewing accessories for all sewing machines in our warehouse and have a team of engineers that can help find that part...

How to retime a sewing machine resetting hook to needle timing

If your sewing machine is missing stitches, or the needle seems to be catching on the bobbin case or hook. Follow these instructions to reset the sewing machine needle timing.

But, first replace the needle with a size 90 brand new sewing machine needle...

How do I wire a new foot control to my lead

How to Wire a New Foot Control to Your Lead – Step-by-Step Guide

When wiring a new foot control to your lead, it's important to follow proper safety and installation procedures. The following instructions are specifically for two-wire leads when...

Motor spins but needle will not move

On the older black cast Singer machines sometimes the motor can spin but there is no drive to move the needle bar. The most common cause of this problem is usually the washer located directly under the de-clutching hand screw which secures the machines...

1

Please, mind that only logged in users can submit questions